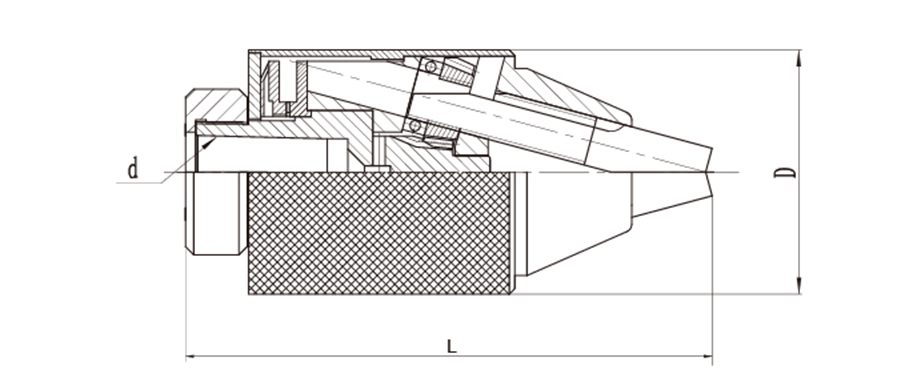

| abin koyi | girman | Matsakaicin iyaka | Kewayon hakowa | Kewayen bugawa | D | L | |||||

| abin koyi | Dutsen | mm | in | mm | in | mm | in | mm | in | mm | in |

| Saukewa: J0113M-B12 | B12 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| Saukewa: J0113M-B16 | B16 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| Saukewa: J0113M-JT2 | JT2 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| Saukewa: J0113M-JT33 | JT33 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 110 | 4.331 |

| J0113-B16 | B16 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 118 | 4.646 |

| Saukewa: J0113-JT33 | JT33 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 118 | 4.646 |

| Saukewa: J0113-JT6 | JT6 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 118 | 4.646 |

| J0116-B16 | B16 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

| J0116-B18 | B18 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

| Saukewa: J0116-JT33 | JT33 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

| Saukewa: J0116-JT6 | JT6 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 130 | 5.118 |

Taper Dutsen Tafi da hakowa chucks masu matse kai kayan aiki ne na musamman waɗanda ake amfani da su don riƙewa da kuma amintar da bututun hakowa da famfo a wurin yayin ayyukan injina.Waɗannan chucks suna da mahimmanci na kowane saitin inji kuma ana amfani da su sosai a masana'antu daban-daban, gami da sararin samaniya, kera motoci, da masana'antu.

Ƙirar ƙwanƙwasa ƙwanƙwasa tana dogara ne akan tsarin taper na Morse, wanda shine daidaitaccen hanya na amintaccen kayan aiki a cikin sandar injin.Taper Dutsen chucks yana da madaidaicin taper na namiji wanda aka ƙera don dacewa da kyau a cikin madaidaicin tef ɗin mace akan sandar injin.Wannan yana ba da haɗin kai mai aminci da kwanciyar hankali wanda ke tabbatar da daidaitattun kayan aiki da kuma rage ƙarancin kayan aiki.

Ɗaya daga cikin mahimman fa'idodin taper Dutsen chucks shine ƙarfinsu.Waɗannan chucks na iya ɗaukar nau'ikan girman kayan aiki da sifofi, gami da raƙuman ruwa, taps, reamers, da injina na ƙarshe.Wannan ya sa su dace don aikace-aikacen injina iri-iri, daga hakowa da tapping zuwa gundura da niƙa.

Taper Dutsen chucks suna samuwa a cikin kewayon girma da salo don dacewa da buƙatun inji daban-daban.Madaidaitan ƙwanƙolin dutsen taper yawanci an tsara su don dacewa da taper ɗin Morse akan sandar injin, yayin da tsayin daka mai tsayi yana da tsayin tapers don ƙara tsauri da daidaito.Hakanan ana samun chucks na taper taper mai saurin canzawa, waɗanda ke ba da damar saurin canje-canjen kayan aiki ba tare da buƙatar ƙarin kayan aiki ko kayan haɗi ba.

Baya ga juzu'insu da sauƙin amfani, ana kuma san ƙwanƙolin ƙwanƙwasa don tsayin daka da amincin su.Wadannan chucks yawanci ana yin su ne daga kayan aiki masu inganci, kamar taurin karfe ko carbide, kuma an ƙera su don jure ƙaƙƙarfan ayyukan injina masu nauyi.Hakanan suna da ƙarancin kulawa kuma suna buƙatar kulawa kaɗan don tabbatar da aiki mai dorewa.

Lokacin amfani da ƙwanƙwasa ƙwanƙwasa taper, yana da mahimmanci don tabbatar da shigar da kayan aiki mai dacewa da daidaitawa don guje wa runout kayan aiki da rage haɗarin lalacewa ga chuck ko sandal ɗin inji.Wannan yawanci ya ƙunshi shigar da kayan aiki a hankali a cikin chuck da kuma ƙarfafa chuck jaws don tabbatar da kayan aiki a wurin.Hakanan yana da mahimmanci don bincika kullun don lalacewa da lalacewa da kuma maye gurbin duk wani abin da aka sawa ko lalacewa kamar yadda ake buƙata.

Gabaɗaya, ƙwanƙwasa dutsen taper da hakowa masu matse kai su ne kayan aiki masu mahimmanci ga kowane aiki na inji.Suna ba da haɗin kai mai aminci da kwanciyar hankali don kayan aiki masu yawa, kuma ƙarfinsu da ƙarfin su ya sa su dace don aikace-aikace iri-iri.Ta hanyar zabar madaidaicin ƙwanƙwasa ƙwanƙwasa don ƙayyadaddun buƙatun injin ku da bin ingantattun hanyoyin shigarwa da kiyayewa, zaku iya tabbatar da ingantaccen aiki da daidaito na shekaru masu zuwa.