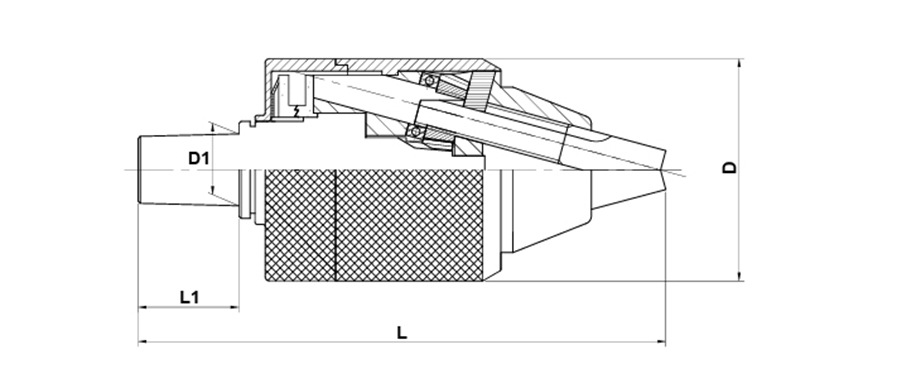

| Samfura | Matsakaicin iyaka | D | D1 | L1 | L | |||||

| mm | in | mm | in | mm | in | mm | in | mm | in | |

| Saukewa: J0113M-MT2D | 1-13 | 0.039-0.512 | 50 | 1.968 | 17.78 | 0.7 | 25 | 0.984 | 124 | 4.882 |

| Saukewa: J0113-MT2D | 1-13 | 0.039-0.512 | 55 | 2.165 | 17.78 | 0.7 | 25 | 0.984 | 131 | 5.157 |

| Saukewa: J0113-MT3D | 1-13 | 0.039-0.512 | 55 | 2.165 | 23.825 | 0.938 | 26.5 | 1.043 | 132.5 | 5.217 |

| Saukewa: J0116-MT2D | 1-16 | 0.039-0.63 | 63 | 2.48 | 17.78 | 0.7 | 25 | 0.984 | 145 | 5.709 |

| Saukewa: J0116-MT3D | 1-16 | 0.039-0.63 | 63 | 2.48 | 23.825 | 0.938 | 26.5 | 1.043 | 146.5 | 5.768 |

Taɓawa da haƙowa chucks masu ɗaure kai tare da haɗaɗɗen ɓangarorin kayan aiki ne masu mahimmanci a cikin shagon injin, suna samar da amintaccen haɗin gwiwa tsakanin kayan aiki da sandar injin.Ɗaya daga cikin shahararrun ƙira na haɗaɗɗen shanks shine Morse short taper, wanda aka yi amfani da shi sosai a ayyukan inji daban-daban.

The Morse short taper wata ƙayyadaddun hanya ce don adana kayan aiki a cikin mashin ɗin injin, wanda aka fi amfani da shi wajen aikin hakowa da tapping.An tsara taper don samar da daidaitattun kayan aiki na kayan aiki da daidaitaccen aiki, yayin da ɗan gajeren tsayi ya ba da izinin ƙira mai ƙima wanda ya dace don amfani a cikin wuraren da aka keɓe.

Ɗaya daga cikin fa'idodin farko na yin amfani da tapping da hakowa chucks masu haɗa kai tare da haɗaɗɗen shanks ta amfani da ƙirar gajeriyar taper ta Morse ita ce haɓakarsu.Ana samun waɗannan chucks masu girma dabam da salo daban-daban don dacewa da buƙatun injina daban-daban, kuma ana iya amfani da su tare da nau'ikan kayan aiki daban-daban, gami da hakowa da famfo.

Wani muhimmin fa'ida na ƙirar gajeriyar taper ta Morse ita ce sauƙin amfani.Haɗaɗɗen shank da chuck yana kawar da buƙatar sassa daban-daban, adana lokaci da ƙoƙari yayin canje-canjen kayan aiki.Bugu da ƙari, ƙaƙƙarfan ƙira na waɗannan chucks yana sa su sauƙin adanawa da jigilar su.

tapping da hakowa chucks masu matse kai tare da haɗaɗɗun shanks ta amfani da ƙirar gajeriyar taper ɗin Morse galibi ana yin su ne daga kayan inganci masu inganci kamar ƙarfe mai tauri ko carbide.Wannan yana tabbatar da cewa suna da ɗorewa kuma suna iya jure wa ƙaƙƙarfan ayyukan injina masu nauyi.Hakanan suna buƙatar kulawa kaɗan, yana mai da su mafita mai tsada ga injiniyoyi.

Don tabbatar da daidaito da ingantaccen aiki, yana da mahimmanci a bi tsarin shigarwa da kulawa da kyau yayin amfani da buɗaɗɗen taɗawa da hakowa kai tsaye tare da haɗaɗɗen shank ta amfani da ƙirar gajeriyar taper ta Morse.Wannan yawanci ya ƙunshi shigar da kayan aiki a hankali a cikin chuck da kuma ƙarfafa chuck jaws don tabbatar da kayan aiki a wurin.Hakanan yana da mahimmanci don bincika chuck akai-akai don lalacewa da lalacewa da maye gurbin duk wani abin da aka sawa ko lalacewa kamar yadda ake buƙata.

A taƙaice, taɓawa da hakowa chucks masu matse kai tare da haɗaɗɗun shanks ta amfani da ƙirar gajeriyar taper ta Morse suna da yawa, masu sauƙin amfani, da kayan aiki masu ɗorewa waɗanda ke da mahimmanci ga ayyukan mashin ɗin daban-daban.Ta zaɓar madaidaiciyar haɗaɗɗen shank chuck don takamaiman buƙatun injin ku da bin ingantaccen shigarwa da hanyoyin kulawa, zaku iya tabbatar da daidaito da ingantaccen aiki na shekaru masu zuwa.